What is waste plastic pyrolysis?

Pyrolysis is a thermal degradation process by which waste plastics can be converted into gaseous fuels and liquid products. Pyrolysis is considered to be one of the most promising ways in plastic waste management and has been shown to be a an economical way. In addition, the pyrolysis of waste plastics can increase the calorific value of the gas and the concentration of H, and can provide high value-added solid products.

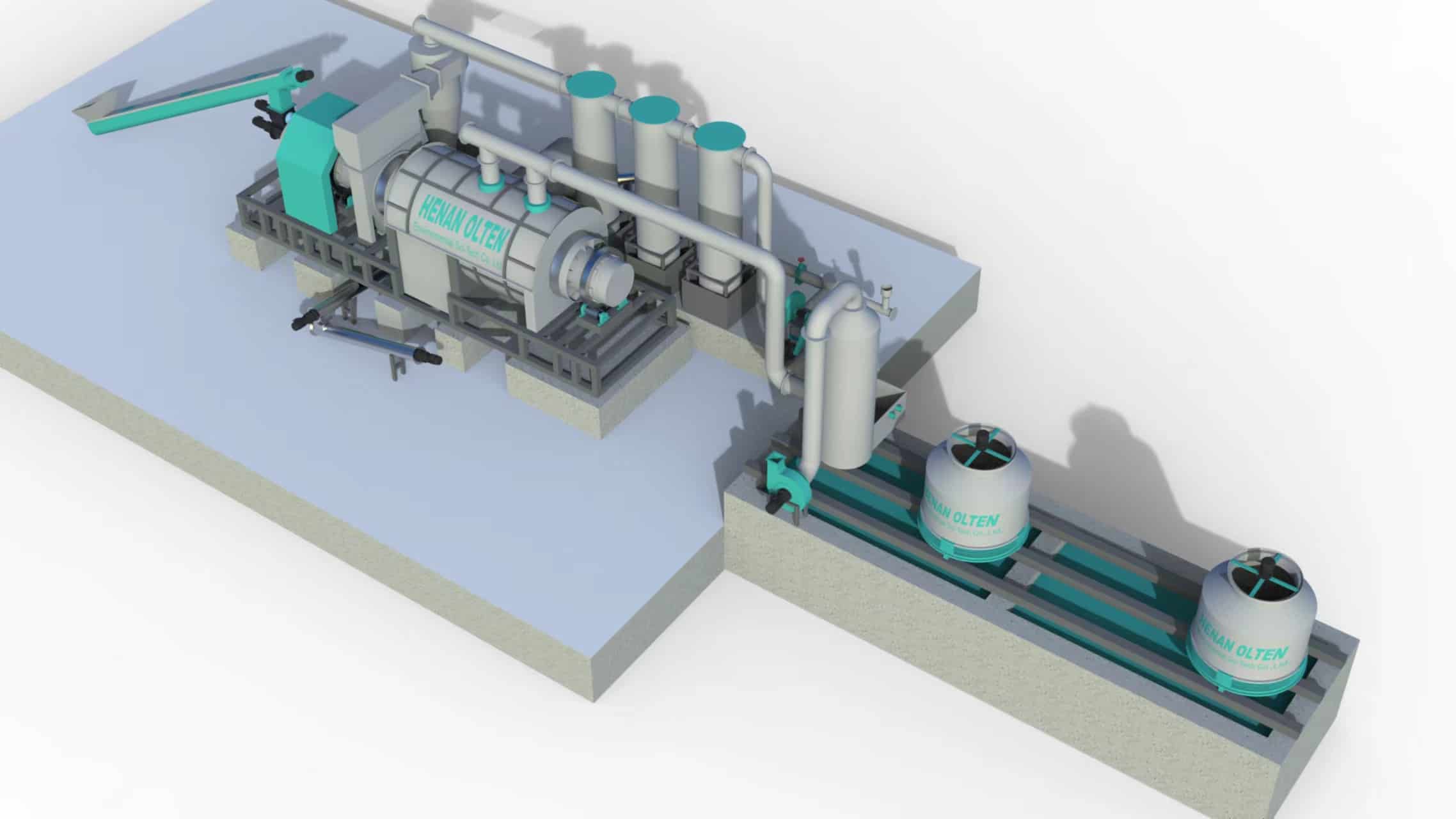

Introduction of waste plastic pyrolysis machine

Waste plastic pyrolysis machine is a machine that can convert waste plastic into fuel oil, carbon black and combustible gas. Because the whole operation process of waste plastic pyrolysis machine conforms to environmental protection standards, and the final products such as fuel oil and carbon black have good markets in many countries, so waste plastic pyrolysis machine projects are becoming more and more popular.

In addition to processing waste plastics, Olten® waste plastic pyrolysis machines can also be used to process waste tires, electronic waste, sludge, various biomass raw materials, and chemical lignite upgrading. Therefore, if you want to process different types of waste, Olten® waste plastic pyrolysis machine will be your perfect choice.

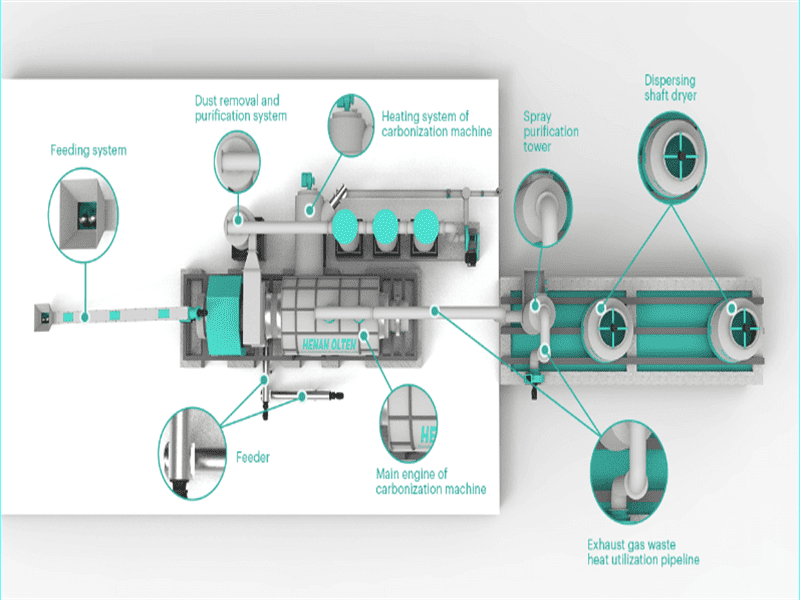

Working principle of waste plastic pyrolysis machine

The waste plastic pyrolysis machine adopts pyrolysis technology, which can decompose waste plastics and other compounds into gaseous, solid or liquid compounds in an oxygen-free environment. The main body adopts a double-layer main drum structure. When working, the materials that meet the requirements will first enter the inner cylinder for drying and preheating treatment, and then enter the outer cylinder for pyrolysis treatment, and finally obtain pyrolysis oil and carbon black. The whole process is smoke-free and pollution-free, in line with national environmental protection requirements.

Advantages of waste plastic pyrolysis machine

Heating method: The flexible heat utilization method adapts to your needs, such as natural gas, liquefied gas and diesel.

High-aluminum refractory castables are used in the interior/inlet/outlet of the combustion chamber, which is resistant to high temperature and has good thermal insulation.

Pyrolysis cylinder: It adopts a double-layer structure, all contacts with materials are made of 304 stainless steel, which is resistant to corrosion and high temperature.

Temperature monitoring points: multiple temperature monitoring points, which can realize accurate temperature measurement through PLC control system.

PLC control: advanced automation technology, Siemens PLC S7-1500 controller or Modbus control.

The equipment adopts modular design: it can realize rapid assembly and debugging, so as to adjust to different installation conditions.

Application of waste plastic pyrolysis machine final product

Fuel oil:

It can be sold directly for profit.

It can be used directly as a fuel in many industries, such as the steel smelting industry.

It can be reprocessed into diesel or gasoline for higher value.

Carbon black:

It can be briquetted and sold as fuel.

It can be processed into powder and used as a raw material for tires, rubber soles or pigments.

Combustible gas:

During the working process, the combustible gas can be directly recycled to heat the furnace, thereby saving the consumption of non-renewable energy.

We also produce Continuous Biomass Pyrolysis Machine, welcome to contact to discuss.