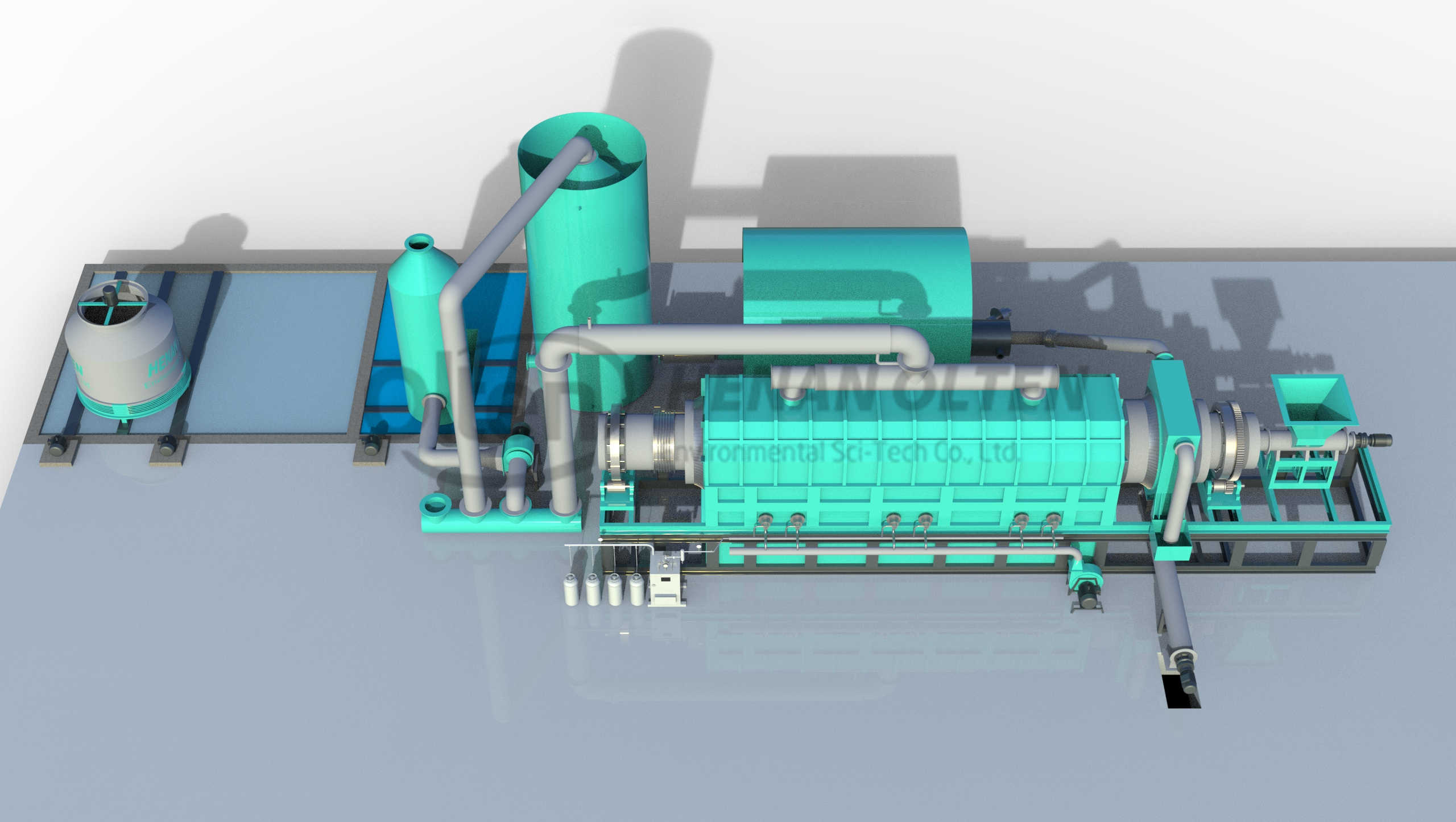

Product Introduction

Olten OLT-D Carbonization Machine is an advanced piece of equipment designed specifically for efficient carbonization processes. It consists of two distinct layers that are carefully engineered to optimize the carbonization environment. The outer structure of the furnace is made from high – quality heat – resistant materials, which can withstand extremely high temperatures during operation. This not only ensures the durability of the equipment but also provides a stable and safe working environment.

Inside the furnace, the two – layer design allows for better heat distribution and utilization. The upper layer is mainly used for the initial stage of carbonization, where the raw materials are gradually heated to a certain temperature range. The lower layer, on the other hand, is dedicated to the further decomposition and carbonization process at higher temperatures. This unique structure enables a continuous and smooth carbonization process, reducing the overall processing time and improving the quality of the carbonized products.

The temperature control system of the Olten OLT-D carbonization furnace is highly precise. It is equipped with advanced sensors that can accurately monitor the temperature inside the furnace in real – time. Based on the feedback from these sensors, the control system can adjust the heating power and maintain the temperature within a very narrow and optimal range. This precise temperature control is crucial for different types of raw materials as it directly affects the carbonization efficiency and the properties of the final products.

Raw Materials

1. Wood

Wood is one of the most common raw materials for carbonization in this furnace. Different types of wood, such as hardwoods (e.g., oak, maple) and softwoods (e.g., pine, spruce), can be used. Hardwoods generally have a higher density and more complex cell structures. During carbonization, they require a relatively higher temperature and longer processing time. The Olten OLT-D carbonization furnace can provide the stable and high – temperature environment needed for hardwood carbonization. For example, oak wood, when carbonized in this furnace, can produce high – quality charcoal with excellent porosity and combustion properties.

Softwoods, with their relatively looser structure, can be carbonized more quickly. The initial heating in the upper layer of the furnace helps to remove the moisture and volatile components in the softwood efficiently. As the process continues in the lower layer, the carbon content in the softwood gradually increases, resulting in good – quality charcoal suitable for various applications such as in the barbecue industry.

2. Biomass Wastes

Biomass wastes, including agricultural residues like straw, husks, and forestry residues, are also suitable raw materials. Straw, for instance, is abundant and has a relatively low density. In the Olten OLT-D carbonization furnace, the upper layer can quickly heat the straw to drive off the water content. Then, in the lower layer, the cellulose and hemicellulose in the straw are decomposed under high temperature, and the remaining lignin is gradually carbonized. This process turns the waste straw into valuable biochar, which can be used for soil improvement. It can enhance soil fertility, increase water – holding capacity, and improve soil structure.

Husks from grains such as rice and corn also have great potential as raw materials. They contain a certain amount of organic matter that can be converted into carbon – rich products through carbonization. The Olten OLT-D design of the furnace allows for better control of the carbonization process of these biomass wastes, minimizing the emission of harmful gases during the process.

3. Industrial Organic Wastes

Some industrial organic wastes, like waste plastics and rubber with high carbon content, can also be processed in the Olten OLT-D carbonization furnace. Waste plastics, when carbonized, can produce carbon black or other carbon – based materials. The first layer of the furnace heats the plastics to make them soften and decompose the additives. In the second layer, under higher temperatures, the long – chain polymer structures in the plastics are broken down, and carbon atoms are rearranged to form carbon – rich products. This provides an environmentally friendly way to recycle industrial waste and reduce the environmental pollution caused by these materials.

Advantages

1. High Efficiency

The Olten OLT-D design significantly improves the carbonization efficiency. By dividing the carbonization process into two stages in different layers, the heat energy is utilized more effectively. The upper layer pre – heats the raw materials and starts the initial decomposition, and the lower layer completes the carbonization at higher temperatures. This continuous process reduces the total carbonization time compared to traditional single – layer furnaces. For example, when carbonizing a batch of wood, the processing time can be reduced by up to 30%, increasing the productivity of the equipment.

2. Energy – saving

The efficient heat distribution and utilization in the Olten OLT-D carbonization furnace also contribute to energy savings. The heat generated in the lower layer can be partially recycled to the upper layer through heat – exchange mechanisms. This reduces the overall energy consumption required for heating the raw materials. In addition, the precise temperature control system ensures that the energy is only used when and where it is needed, avoiding unnecessary energy waste. Over a long – term operation, the energy – saving effect is quite remarkable, reducing the production cost of carbonized products.

3. High – quality Products

The stable and precisely controlled carbonization environment in the furnace results in high – quality carbonized products. The uniform heat distribution in both layers ensures that the raw materials are carbonized evenly. This leads to better physical and chemical properties of the final products. For example, the charcoal produced has a more regular pore structure, higher carbon content, and lower ash content. The biochar from biomass wastes has better stability and activity for soil improvement applications. The carbon – based products from industrial organic wastes also have more consistent quality, meeting the requirements of different industries.

4. Environmental Protection

The Olten OLT-D carbonization furnace is designed with environmental protection in mind. During the carbonization process, the emissions of harmful gases such as carbon monoxide and dioxins are minimized. The well – designed combustion chamber and gas purification system in the furnace can effectively treat the flue gas generated during carbonization. The heat – recovery system also reduces the energy consumption from external sources, indirectly reducing the carbon footprint of the production process. This makes the equipment more environmentally friendly compared to some traditional carbonization methods.

Applications

1. Energy Industry

In the energy industry, the charcoal produced by the Olten OLT-D carbonization furnace can be used as a high – quality fuel. It has a high calorific value and relatively clean combustion characteristics. In some small – scale power generation systems or heating systems, this charcoal can replace traditional fossil fuels to a certain extent. For example, in rural areas or remote regions, where access to traditional energy sources may be limited, the charcoal produced by the furnace can be used for household heating and cooking, providing a sustainable and local energy solution.

2. Agriculture

The biochar produced from biomass wastes in the furnace has extensive applications in agriculture. When added to the soil, it can improve soil quality. It can act as a soil conditioner, increasing the soil’s water – holding capacity, improving soil porosity, and enhancing nutrient retention. This helps plants grow better, increases crop yields, and reduces the need for chemical fertilizers. In addition, biochar can also be used in composting processes to accelerate the decomposition of organic matter and improve the quality of the compost.

3. Chemical Industry

In the chemical industry, the carbon – based products from the carbonization of industrial organic wastes can be further processed. The carbon black produced from waste plastics can be used as a filler in rubber and plastic products, improving their mechanical properties and durability. The carbon – rich materials can also be used in the production of activated carbon, which has wide applications in water purification, air purification, and chemical separation processes. The Olten OLT-D carbonization furnace provides a reliable source of raw materials for these chemical processes.

4. Metallurgical Industry

In the metallurgical industry, the high – quality charcoal produced by the furnace can be used as a reducing agent in some metal smelting processes. For example, in the production of iron and steel, charcoal can replace part of the coke, reducing the environmental impact of the smelting process. The unique properties of the charcoal, such as its high carbon content and good reactivity, make it an ideal reducing agent in certain metallurgical applications.

Conclusion

In conclusion, OLT-D Carbonization Machine is a highly versatile and efficient equipment with broad applications in various industries. Its ability to handle different raw materials, combined with its numerous advantages, makes it a valuable asset in the production of carbonized products for both economic and environmental benefits.