I. Product Introduction

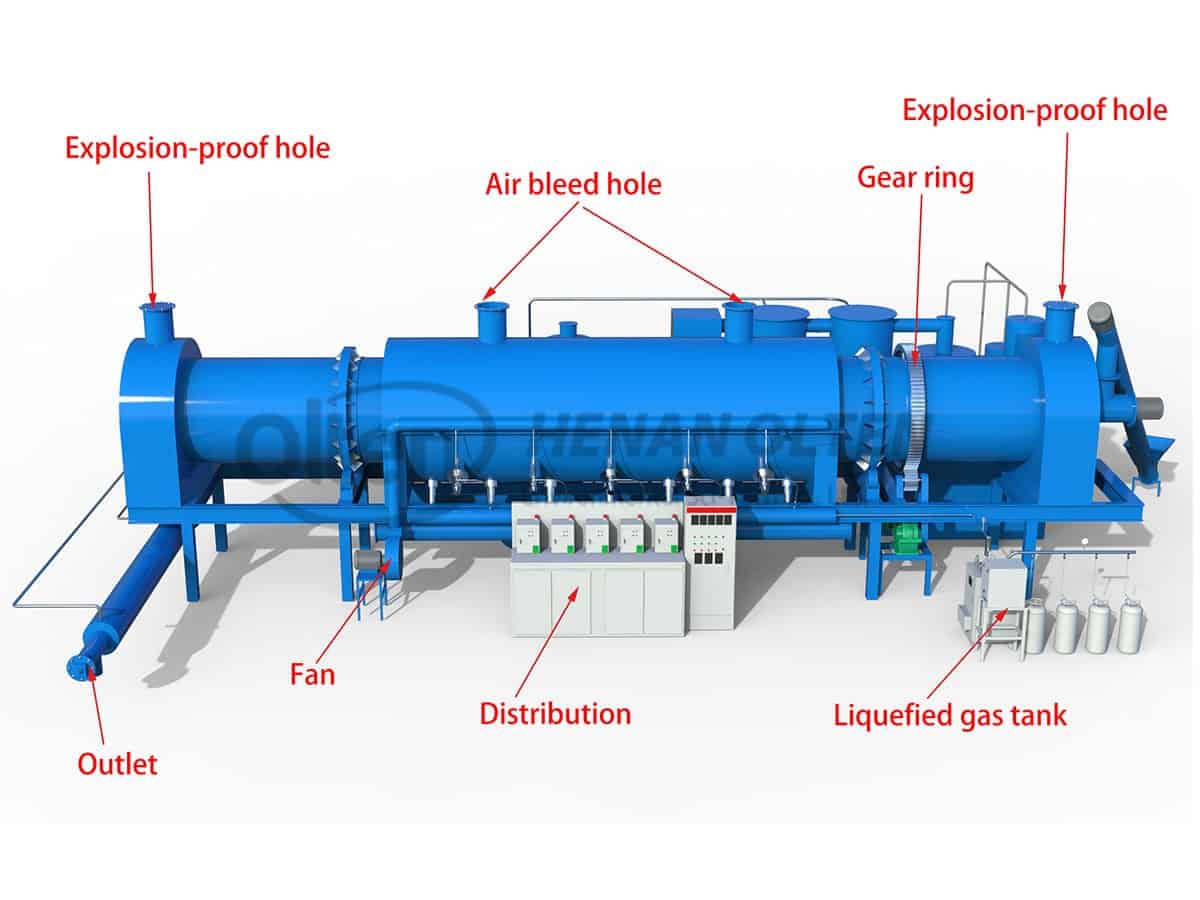

The continuous carbonization furnace is a kind of equipment specially used for carbonization of materials. It is usually composed of a feeding device, a heating chamber, a carbonization reaction zone, a cooling device and a discharging device. The heating chamber can provide a stable and adjustable high temperature environment to meet the temperature conditions required for carbonization of different materials. The carbonization reaction zone is the core part, where the material undergoes a carbonization reaction under high temperature and a specific atmosphere. The cooling device can quickly and effectively reduce the temperature of the carbonized product, and the discharging device ensures that the carbonized product is discharged smoothly.

II. Advantages

1. Efficiency

– Compared with the intermittent carbonization furnace, the continuous working mode does not require frequent feeding, heating, cooling, discharging and other operations, which greatly improves the production efficiency. For example, when processing a large amount of biomass materials, more materials can be processed per unit time.

2. Stable product quality

– Due to its stable temperature control and continuous reaction process, the quality of the carbonized product is relatively uniform. For example, when producing activated carbon, the continuous carbonization furnace can ensure that the adsorption performance of the activated carbon remains relatively stable between each batch.

3. High energy utilization rate

– During the operation of the continuous carbonization furnace, the heat can be well recovered and utilized. During the heating process, the waste heat generated can be used to preheat the new materials, reducing energy waste.

III. Application

1. Biomass carbonization field

– Used to carbonize biomass materials such as wood and straw to produce biochar. Biochar can be used as a soil conditioner to improve soil fertility and increase the soil’s ability to retain water and fertilizer.

2. Carbon material preparation

– When preparing high-end carbon materials such as carbon fibers and carbon nanotubes, the continuous carbonization furnace can provide precise carbonization conditions, which helps to improve the performance of these materials.