Purpose of coconut shell charcoal.

As a completely natural and environmentally friendly biofuel, coconut shell charcoal can be used as a substitute for fuelwood, kerosene and other fossil fuels. In addition, the most popular choice for shisha/hookah charcoal on the market is coconut shell charcoal.

How to make shisha/hookah charcoal from coconut shell.

Crushed and dried coconut shell

According to the size and moisture content of the coconut shell , select the appropriate crushing and drying equipment for processing.

Carbonization of coconut shell into coconut shell charcoal

B1.If the coconut shell size is too large, we recommend the use of our hoisting carbonization furnace and horizontal carbonization furnace.

If the coconut shell size is less than 3cm, it is recommended to use our continuous carbonization furnace and sawdust carbonization machine.

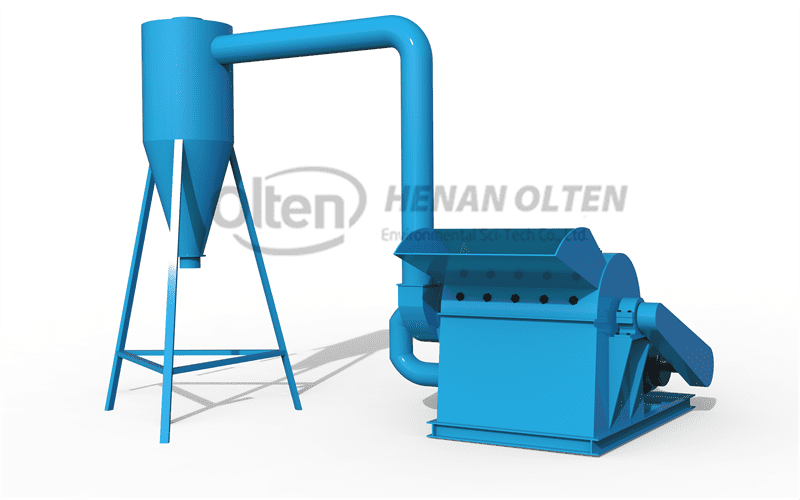

Crushed coconut shell charcoal

After carbonization, coconut shell charcoal generally retains the shell shape or fragments. Before making shisha/hookah charcoal, such coconut shell charcoal needs to be ground into powder. This makes it easier to shape and at the same time can improve the quality of the finished product.

It is recommended to use Hammer mill.

Mix coconut shell charcoal powder with water and adhesive

Because coconut shell charcoal powder is not sticky, you need to add water and adhesives to help it shape.

It is recommended to use Wheel mill mixer and Adhesive mixing barrel.

The ratio of coconut shell charcoal powder, water and adhesive is recommended to be controlled at 70%, 25% and 5%.

Knead the mixed materials with your hands and do not loosen, indicating that the humidity has reached the standard.

Adding adhesive can make the shisha/hookah charcoal stronger and the surface smoother. The most common binders are corn starch or tapioca starch, which are food-grade and have no pollution after burning.

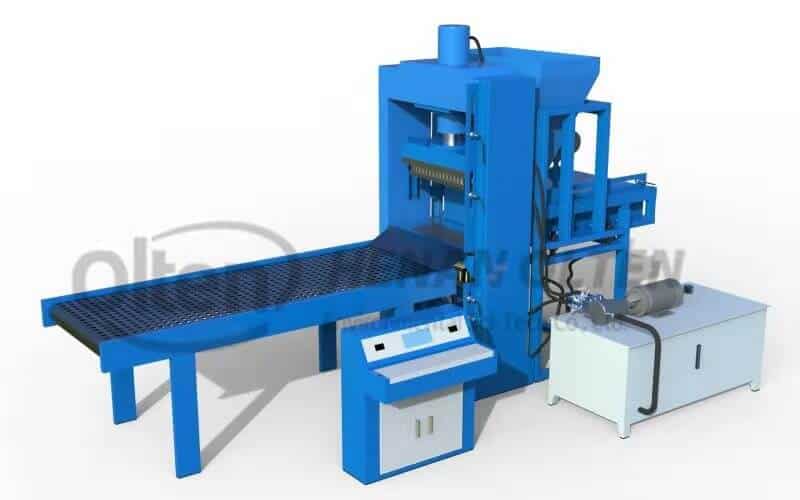

Coconut shell charcoal to make shisha/hookah charcoal

Shisha/Hookah charcoal production process: the coconut shell charcoal powder that has been fully bonded and stirred is manually or conveyed into the hopper, and pressure is provided by the hydraulic pump station. The material is stamped and formed under the action of the mold, and the finished product is sent out via the conveyer belt.

It is recommended to use shisha/hookah charcoal briquette machine.

Dried of shisha/hookah charcoal

The finished shisha/hookah charcoal must be dried before it is used as a fuel or sold on the market. There are usually two drying methods, one is drying in the sun, and the other is use machine to dry.

Dry in the sun.

Pay attention to the drying environment to prevent dirt and other impurities from adhering to the surface, and also pay attention to rain or accidental damage.

Use machine to dry.

The box dryer is composed of a heat source system, an exhaust system, a heat preservation room, a drying rack and a tray. The whole box adopts a fully enclosed structure, and the hot air circulates in the box to rationally exhaust the hot and humid air. It has the characteristics of high thermal efficiency, energy saving, and good drying effect.

Shisha/hookah charcoal made from coconut shell, has become a new type of high value-added charcoal product due to its high-end uses and special properties, which has good market prospects and economic benefits.