How to make coconut shell charcoal?

If the coconut shell size is too large, we recommend the use of our hoisting carbonization furnace and horizontal carbonization furnace.

If the coconut shell size is less than 3cm, it is recommended to use our continuous carbonization furnace and sawdust carbonization machine.

How To Choose The Most Suitable Carbonization Furnace (step by step)

How to crush coconut shell charcoal?

After carbonization, coconut shell charcoal generally retains the shell shape or fragments. Before making charcoal balls, such coconut shell charcoal needs to be ground into powder. This makes it easier to shape and at the same time can improve the quality of the finished product.

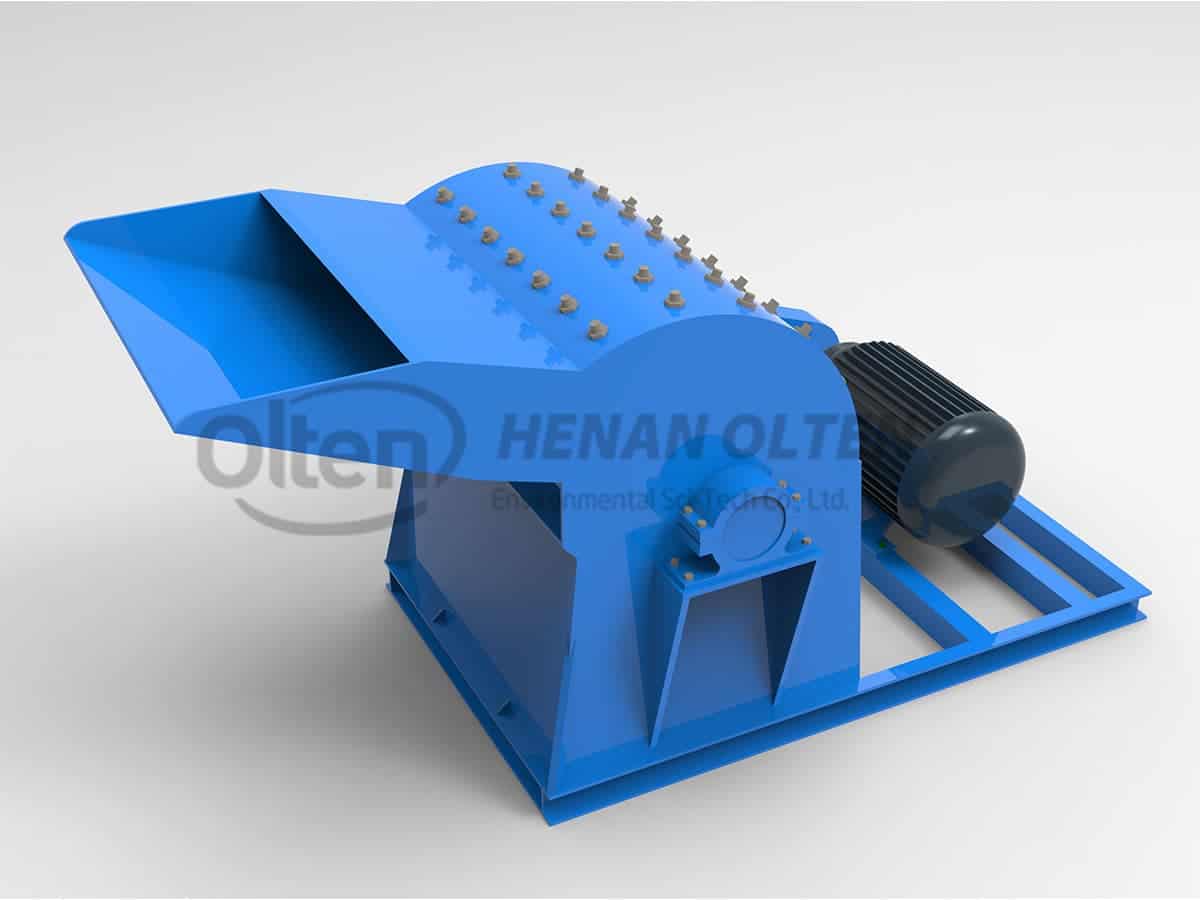

It is recommended to use Hammer mill.

How to making coconut shell charcoal balls?

Mix coconut shell charcoal powder with water and adhesive.Because coconut shell charcoal powder is not sticky, you need to add water and adhesives to help it shape.

It is recommended to use Wheel mill mixer and Adhesive mixing barrel.

Charcoal Balls production process: the coconut shell charcoal powder that has been fully bonded and stirred is manually or conveyed into the hopper.The material is stamped and formed under the action of the mold, and the finished product is sent out via the conveyer belt.

It is recommended to use charcoal ball briquette machine.