What is biomass pyrolysis?

Biomass pyrolysis refers to the process of converting biomass into low molecular substances such as charcoal, liquid and gas through thermochemical conversion under the condition of isolating air or supplying a small amount of air. Biomass pyrolysis technology can convert biomass into gas, liquid, solid products, etc. with lower cost and continuous production process, which reduces the volume of biomass and facilitates storage and transportation. At the same time, it can also extract high value-added chemicals from bio-oil.

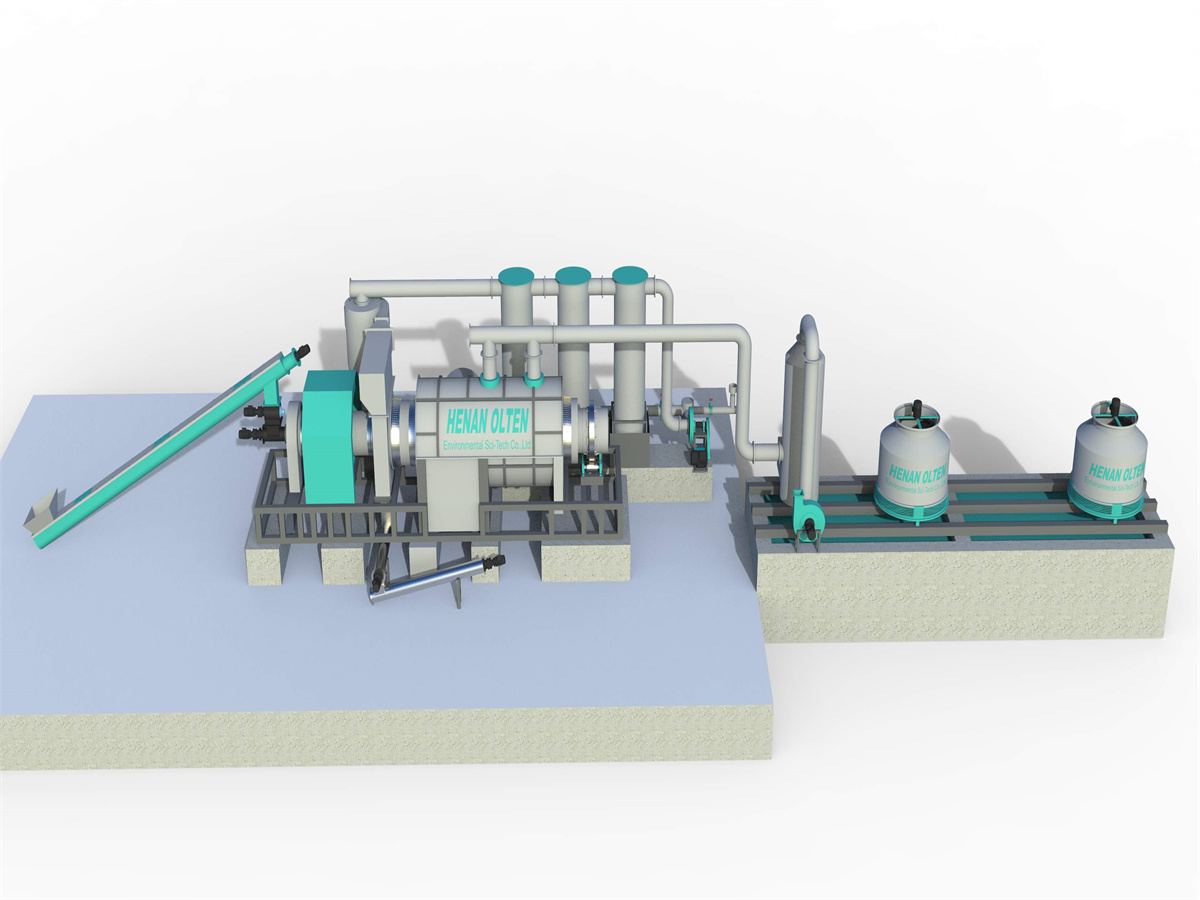

Introduction to biomass pyrolysis machine

Biomass pyrolysis machine adopts a double-layer main drum structure, and the cylinder body is made of stainless steel, which is resistant to high temperature and corrosion. At the same time, a new indirect heating method is adopted to improve the thermal efficiency and increase the service life of the equipment.The whole operation is smoke-free and pollution-free, which is in line with the national environmental protection policy.

Working principle of biomass pyrolysis machine

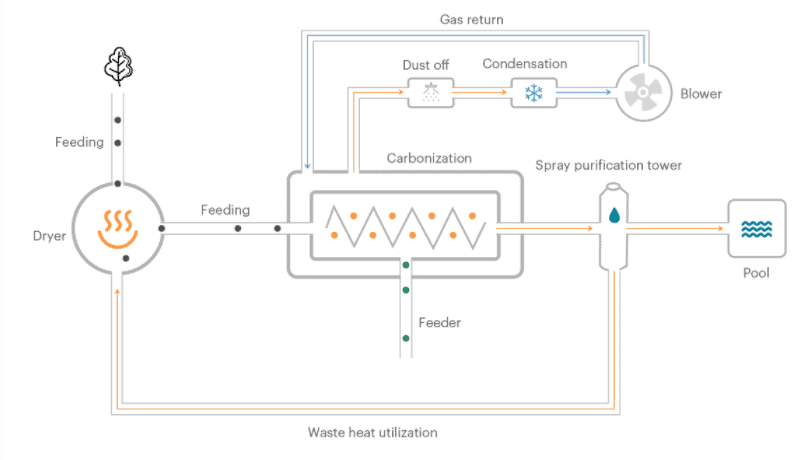

Crushing & drying

Feeding requirements: material moisture ≤ 15%, and material with size ≤ 30mm.

Pyrolysis & discharge

The main body of the carbonization machine is formed by nesting inner and outer cylinders, and the main combustion of the outermost layer adopts ceramic fiber flame retardant cotton for thermal insulation; when working, the materials that meet the requirements are advanced Enter the inner cylinder for drying and preheating treatment, and then enter the outer cylinder for carbonization treatment.

Combustible gas generation

About 20 minutes after feeding, the combustible gas is generated. First, it enters the cyclone dust removal system for cleaning, desulfurization and dust removal, and then enters the condenser to be separated into wood vinegar and tar. The remaining gas is led by the induced draft fan to the outside of the main body for combustion The chamber is ignited and heated, and the hot air flow generated by the combustion chamber is introduced into the main combustion chamber by the fan, and the main body is heated.

Reuse of hot flue gas

Part of the waste heat flue gas can be used to heat the dryer, and the remaining flue gas is discharged after the dust removal system (water cleaning, water spray, etc.) and flue gas treatment equipment reaches the standard.

Advantages of biomass pyrolysis machine

Heating method: The flexible heat utilization method adapts to your needs, such as natural gas, liquefied gas and diesel.

High-aluminum refractory castables are used in the interior/inlet/outlet of the combustion chamber, which is resistant to high temperature and has good thermal insulation.

Pyrolysis cylinder: It adopts a double-layer structure, all contacts with materials are made of 304 stainless steel, which is resistant to corrosion and high temperature.

Temperature monitoring points: multiple temperature monitoring points, which can realize accurate temperature measurement through PLC control system.

PLC control: advanced automation technology, Siemens PLC S7-1500 controller or Modbus control.

The equipment adopts modular design: it can realize rapid assembly and debugging, so as to adjust to different installation conditions, clearly assign the function of module unit, and expand and add external components (such as packaging machine, conveyor belt, ORC, etc.)

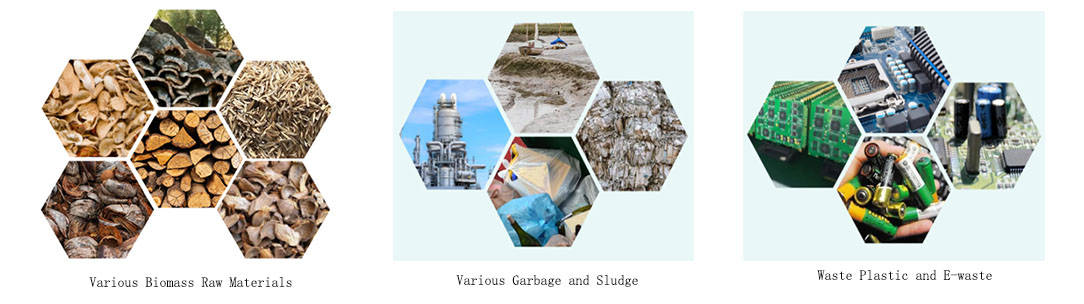

Application fields of biomass pyrolysis machine

The Olten® biomass pyrolysis machine is suitable for all types of biomass pyrolysis in wood form and can logs, sawdust, wood chips, bamboo, coconut husks, rice husks, crop straw and many other products are converted into high-value resources. At the same time, it can also be used for pyrolysis treatment of plastics, tires, sludge, domestic waste and electronic waste, etc.

Biomass pyrolysis machine offer you the possibility of obtaining all kinds of products, including bio-oils of various kinds, biochar, carbon, charcoal, syngas and many more. When you’re looking to maximize your benefits,We can help you design a plan, Olten® equipment is a perfect choice.