Application

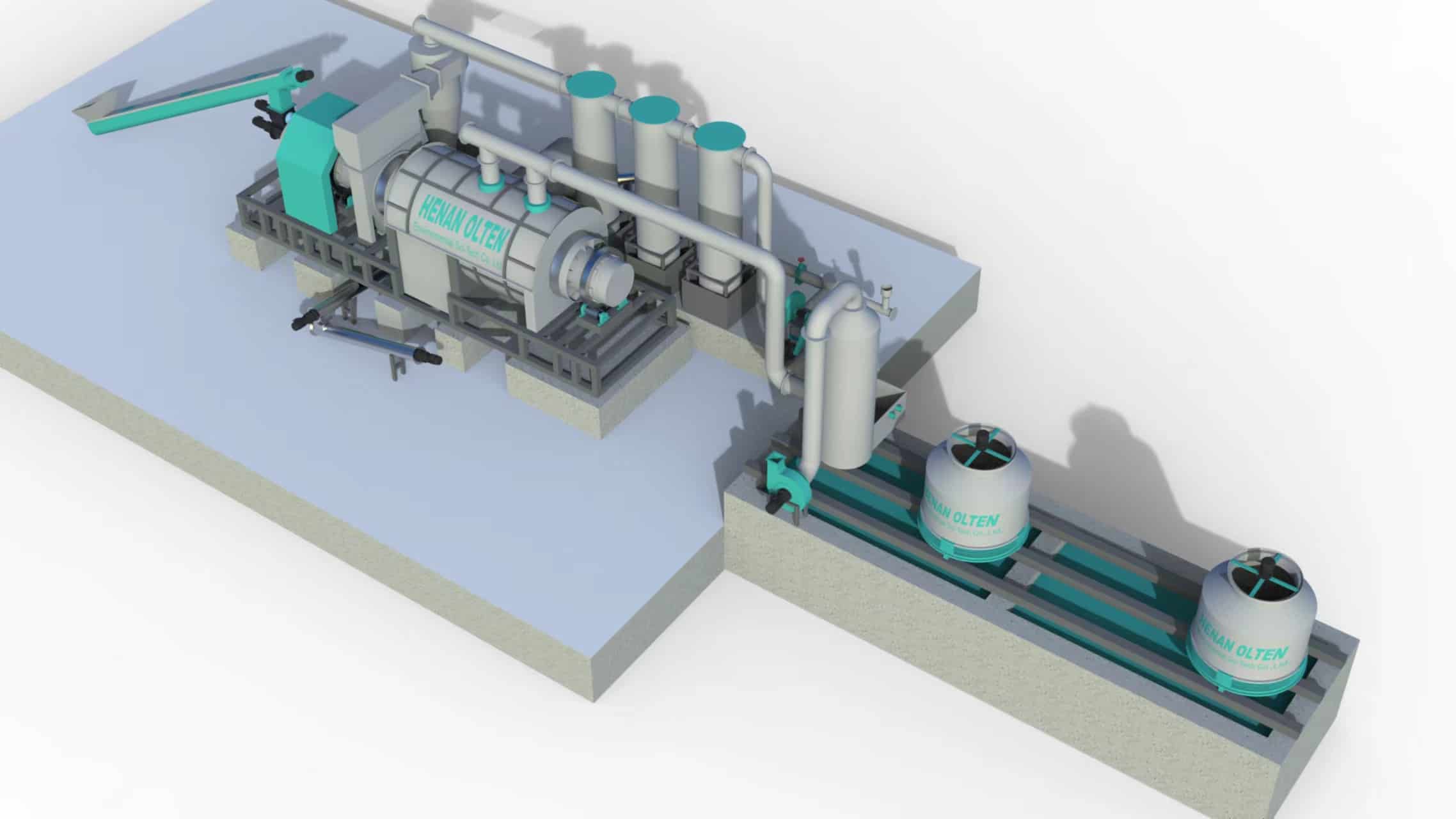

Circuit board treatment: The circuit board carbonization furnace adopts the dry distillation thermal cracking process, which can crack the waste circuit board at high temperature in the absence of oxygen, solve the problem of traditional circuit boards being difficult to crush and organic matter coating metals, and improve the metal recovery rate. By cooling and screening to separate metals, non-ferrous metals can be recovered. The metal recovery efficiency is high, the separation effect is good, and it is environmentally friendly and pollution-free. The generated combustible gas can also be used to heat the carbonization furnace to achieve the recycling of combustion energy.

Battery recycling: Taking the carbonization furnace to treat waste batteries as an example, the feeding structure receives the finely crushed battery materials from the battery crusher. In the carbonization furnace, the temperature rise section makes the electrolyte volatilize, the gas is collected, and the high temperature section carbonizes the adhesive and diaphragm paper. The released gas is also collected, thereby realizing the separation of carbonized powder and the positive and negative electrodes of the battery, and improving the recycling rate of battery materials.

Precious metal recovery: Multi-hearth furnace pyrolysis technology can be used to separate and recover precious metals from electronic waste. It can separate and recover 98% of precious metals, such as copper, gold, silver and palladium. The final product is a homogeneous concentrate of precious metals, which is usually higher in grade than traditional mining concentrates and can achieve 100% recovery, while reducing harmful emissions associated with traditional precious metal recovery.

Preparation of carbon materials: Solid carbon can be obtained after carbonization of electronic waste. This carbon has the characteristics of high calorific value and low ash content, and can be used in energy, agriculture and other fields. For example, the carbon composite material prepared by integrated carbonization of waste cotton fabric and bamboo powder can shield more than 99.9% of electromagnetic waves, and has good fire resistance and light and electricity energy conversion performance, and has potential applications in flexible electronic devices.

Prospects

Policy support: With the enhancement of environmental awareness and the promotion of relevant policies, such as under the goal of “carbon neutrality and carbon peak”, the requirements for electronic waste treatment are getting higher and higher. Carbonization technology, as an environmentally friendly and efficient treatment method, conforms to policy orientation and will receive more policy support and capital investment, which will help promote technology and industry development.

Increase in resource recovery value: Electronic waste contains a large amount of valuable resources. With the increasing problem of resource shortage, the advantages of carbonization technology in improving resource recovery rate will be more prominent. It can recover more precious metals, carbon materials, etc. from electronic waste, maximize the utilization of resources, bring higher economic value, and promote the development of related industries.

Technological innovation and improvement: With the continuous advancement of science and technology, carbonization technology will also continue to innovate and improve, such as developing more efficient carbonization equipment, optimizing carbonization process parameters, and improving automation and intelligence levels, so as to further improve the efficiency of electronic waste treatment and resource recovery effect, reduce treatment costs, and enhance the competitiveness of carbonization technology.

Synergistic development with other technologies: Carbonization technology can be combined with other electronic waste treatment technologies, such as mechanical treatment, chemical treatment, etc., to form a synergistic effect and achieve more comprehensive and efficient electronic waste treatment and resource recovery. For example, the different components in electronic waste are initially separated by mechanical crushing and sorting, and then the carbonization technology is used to treat the organic part, and finally the recovered metals are refined by chemical methods.

Market demand growth: With the continuous upgrading of electronic equipment, the amount of electronic waste generated will continue to increase, and the demand for electronic waste treatment technology will also continue to grow. As a treatment method with good application prospects, carbonization technology will occupy a larger share in the market and promote the development and growth of the electronic waste treatment industry.