Product Introduction

Disc wood crusher machine integrates slicing and crushing, and is a new type of wood crushing equipment. It is one of the main equipment in the crushing of raw materials in the charcoal making production process.

Disc wood crusher machine can process coarse logs, branches, and other raw materials into sawdust at one time.

The disc wood crusher is widely used in the production fields of papermaking, edible fungus, machine-made charcoal, particle board, sawdust board, high density board, medium fiber board, and so on.

We sell custom small wood crusher machines at reasonable prices.

Large-scale wood shredders can also be customized, with a maximum capacity of up to 10 tons

disc wood crusher machine

Working Principle

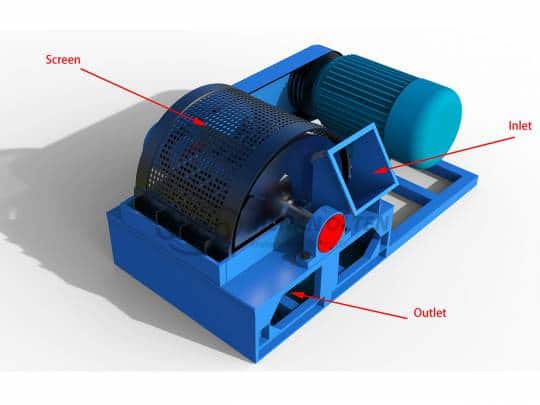

When the wood crusher machine is working, the raw materials pass through the inlet and pass through the high-speed rotating rotor inlaid with blades and hammers to cut and smash the materials, and discharge the cut and smashed products with high air pressure.

disc wood crusher machine

Core Components

- Cutter head: manganese steel material, high hardness and wear resistance.

- Blade: High-speed alloy steel, durable and non-curling.

- Hammer: 65Mn, quenched to increase the toughness and wear resistance of the hammer.

- Screen: No. 45 cold-rolled plate, with good acid and alkali resistance, good rust resistance, and a variety of models can be customized.

Product Advantages

- (1) Wide application range, low cost, good finished product, and high stability.

- (2) It can be driven by electric motors, diesel engines, and gasoline engines, and can realize mobile operation.

Product Parameter

| Model | Power(kw) | Processing Capacity(t/h) | Weight(kg) | Size(mm) |

| 450 | 7.5 | 0.5-0.8 | 180 | 1300*600*700 |

| 500 | 15 | 0.8-1 | 280 | 1500*700*900 |

| 800 | 30 | 1-1.5 | 500 | 1700*800*1350 |

| 1050 | 55-75 | 4-6 | 900 | 2500*1200*1200 |

| 1200 | 75-90 | 6-8 | 1800 | 2900*1750*1400 |

| 1500 | 110-132 | 8-10 | 2400 | 3200*1850*1500 |

| 1800 | 132-160 | 10-15 | 2800 | 3500*1900*1650 |