Wood Charcoal Briquette Production Line

1.Advantages of charcoal

Long burning time, high calorific value, no smoke, no explosion, environmental protection and economy.

2.Applicable fields of charcoal

Charcoal can be used for domestic combustion, boilers, barbecues, fireplace heating, power plants and other aspects.

In addition, due to its unique microporous structure and super adsorption capacity, it is widely used in many fields such as food, pharmacy, chemical industry, metallurgy, national defense, agriculture and environmental protection.

3.Working principle of carbonization

The carbon-containing biomass materials are subjected to dry distillation and oxygen-free heating, and are pyrolyzed into combustible gas, tar and charcoal through moisture removal.

Flammable gas can be collected and used as fuel.

Tar can be used after separation and purification.

Note: In summary, the working principle of carbonization is the same, but according to different materials, different finished product requirements and output requirements, the selected equipment is also different. To be engaged in the carbonization industry, it is particularly important to choose suitable carbonization equipment.

4.Wood Charcoal Briquette Production Line raw materials

Wood charcoal briquette production line has a wide range of raw materials,such as wood logs, bamboo, coconut shells, palm shells, wood chips, rice husks, nut shells, walnut shells and various biomass raw materials.

wood charcoal briquette raw materials

5.Wood Charcoal Briquette Production Line products

wood charcoal briquette products

6.Wood Charcoal Briquette Production Line process flow

-

- Production process: Crushing→Re-crushing→Dryer→Forming→Carbonization

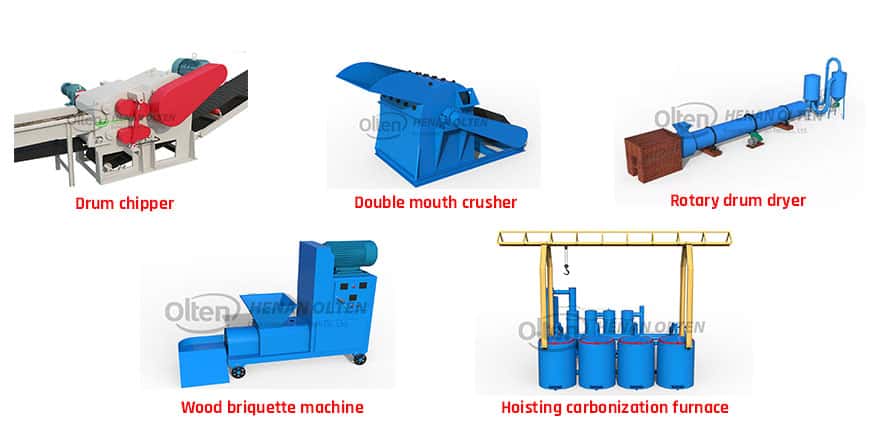

- Production line equipment matching: Drum chipper→Double mouth crusher→Rotary drum dryer→Wood charcoal briquette machine→Hoisting carbonization furnace

wood charcoal briquette production line

7.Wood Charcoal Briquette Production Line product description

- A.Drum chipper is a special equipment for producing all kinds of high-quality wood chips. It can cut logs and small-diameter wood into high-quality wood chips with uniform size and flat cuts.

- B.Double mouth crusher is a fine crushing equipment that can process all kinds of wood, wood scraps, branches, branches, wood chips, board trim, bark, bamboo, bamboo bark and other raw materials into sawdust at one time.

- C.Rotary drum dryer is one of the traditional drying equipment, which is reliable in operation, flexible in operation, strong in adaptability, and large in processing capacity. The diameter and length of the equipment are determined according to the drying requirements.

- D.Wood charcoal briquette machine is a kind of forming equipment, which mainly passes qualified sawdust and wood materials or biomass materials (under 5mm in size, 12% moisture) through spirals, high pressure forming cylinders and heating rings. The machine-made rod is formed under high temperature and high pressure.

- E.Hoisting carbonization furnace is an environmentally friendly and smokeless carbonization equipment. It can not only carbonize machine-made rods, but also directly carbonize raw materials such as logs, wood blocks, coconut shells, and tree bark.

wood charcoal briquette production line product description

8.Can provide free production line design

When you plan to configure a carbonization production line, please let us know your details.

These materials include:

- Raw material type, size, moisture

- Plant size

- Transformer capacity

- Type and size of finished product

- Demand for output

- As detailed as possible, the best, in order to customize your own carbonization production line equipment, and we will provide you with 3D site planning diagrams for free.