Product introduction

Shisha Charcoal Briquette Machine is the latest hydraulic waterpipe charcoal tableting equipment developed by our factory.It is one of the main equipment for charcoal briquette.

The equipment can press blue charcoal, coke dust, charcoal powder, ash powder, fertilizer and other powders, and make the materials into agglomerates through high pressure.

The machine has the advantages of high output, simple operation, excellent performance and convenient maintenance.

Shisha Charcoal Briquette Machine can be molded in one second through high pressure, and the block density is high, and various molds can be replaced according to different needs.

shisha charcoal briquette machine

Working Principle

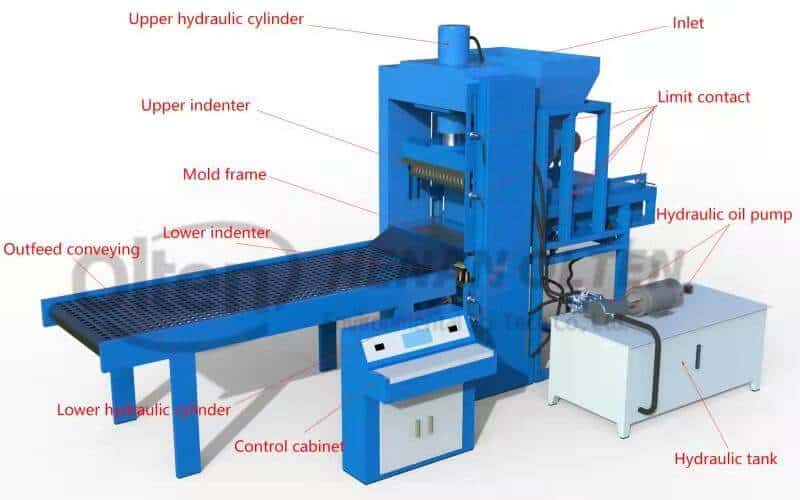

When the Shisha Charcoal Briquette Machine is working, the materials after bonding and mixing are injected into the hopper manually or by a conveyor belt, and pressure is provided by a hydraulic pump station.

The rear cart pushes the material to the forming mold, and the upper mold pressure head presses down to put the material in a static state.

The next stamping and forming, the lower stamping head pushes to the platform, after the cart pushes the material to the conveyor belt, and then conveys it out by the conveyor belt.

shisha charcoal briquette machine

Core Components

- Upper and lower die indenters: heat-treated No. 45 steel, with good wear resistance, high hardness and durability.

- Piston column: No. 45 steel with heat treatment, good wear resistance, high hardness and durability.

- Grid discharging conveying: It is made of galvanized material, which is durable and corrosion-resistant.

Product Advantages

- (1)The specially designed feeding and discharging device has a high degree of automation.

- (2)The special structure installation makes the replacement and maintenance of the upper and lower guide rails and molds convenient and quick.

- (3)The mold is hardened at high temperature, which is more wear-resistant and has a longer service life.

Product Parameter

| Model | Power(kw) | Output(b/h) | Weight(kg) | Size(mm) | Conveying Size(mm) |

| HYJ450 | 16.5 | 10800-15000 | 2500 | 3970*1100*2600 | 2500*700 |