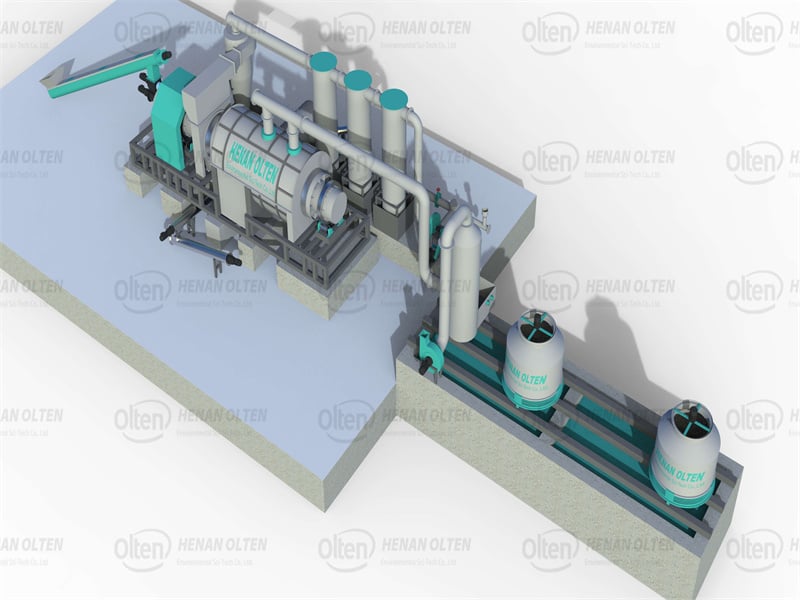

Continuous carbonization machine product description

Continuous carbonization machine, also known as biochar machine, biomass pyrolysis machine , or biomass charcoal making machine. It can truly realize multiple functions in one machine, which can be used for biomass carbonization such as wood chips, coconut shells, bamboo chips, straws, etc., as well as carbonization of sludge, domestic waste and electronic waste. The whole process is smoke-free and pollution-free.

Continuous carbonization machine newly developed by our company adopts a double-layer main drum structure, and the cylinder body is made of stainless steel, which is resistant to high temperature and corrosion. At the same time, a new indirect heating method is adopted to improve the thermal efficiency and increase the service life of the equipment.

The traditional carbon-making method cannot achieve continuous carbonization, resulting in low economic benefits; and the carbonization process will release a lot of smoke and dust, causing air pollution, which is not in line with the national environmental protection policy.

Continuous carbonization machine working principle

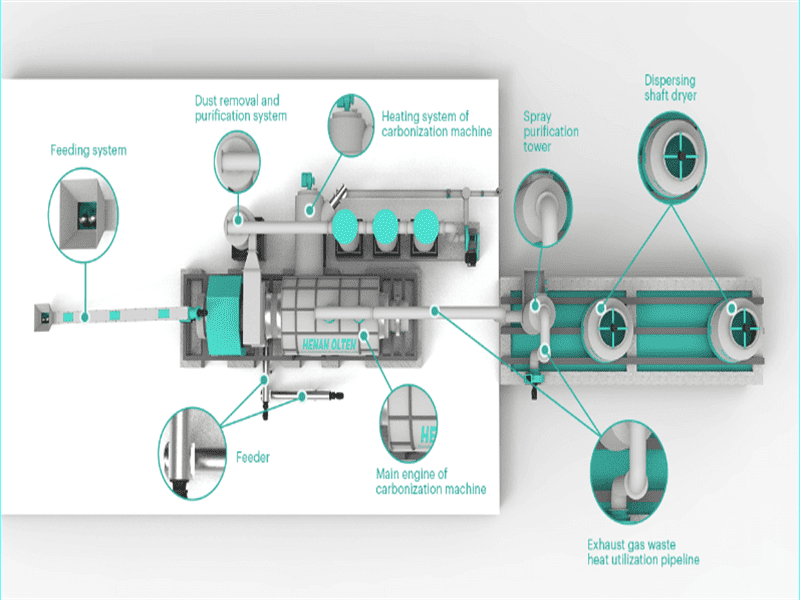

Crushing & drying – Feeding requirements: material moisture≤15%, material size≤30mm.

Carbonization & discharge – the main body of the carbonization machine is formed by nesting inner and outer cylinders, and the main combustion of the outermost layer is treated with ceramic fiber flame retardant cotton for heat preservation; when working, the materials that meet the requirements enter the inner cylinder first Dry and preheat treatment, and then enter the outer cylinder for carbonization treatment.

Combustible gas generation – about 20 minutes after feeding, flammable gas is generated. First enter the cyclone dust removal system for cleaning, desulfurization and dust removal, and then enter the condenser to separate the wood vinegar and tar. The remaining gas is led by the induced draft fan to the external combustion chamber of the main body for ignition and heating, and then the hot air flow generated by the combustion chamber is introduced into the main combustion chamber by the fan. , and continue to heat the body.

Reuse of hot flue gas – part of the waste heat flue gas can be used to heat the dryer, and the remaining flue gas is discharged after being treated by the dust removal system and flue gas purification equipment.

Continuous carbonization machine advantages

“U” type screw feeder system: frequency conversion speed regulation, uniform feeding; good sealing, no dust; open design, easy to maintain.

Carbonization cylinder: It adopts a double-layer structure, the inner layer is pre-dried, and the outer layer is carbonized. All contacts with materials are made of 304 stainless steel, which is resistant to corrosion and high temperature.

Transmission mode: inner cylinder transmission, thickened gear ring and roller ring to ensure the safe operation of the equipment.

Heating method: There are various heating methods, such as natural gas, liquefied petroleum gas and diesel oil.

Good thermal insulation: high-aluminum refractory castables and ceramic fiber insulation cotton are used to withstand high temperature and reduce heat loss.

PLC control: advanced automation technology, Siemens PLC S7-1500 controller or Modbus control.

Continuous carbonization machine parameter

| Model | Power | Weight | Output | Dimension | Control method | Service life |

| OLT-8 | 42kw | 15tons | 100-200kg/h | 8.1*2*.25m | PLC(manual+automatic) | 5-8years |

| OLT-12 | 49kw | 20tons | 200-300kg/h | 9*2.2*3.4m | PLC(manual+automatic) | 5-8years |

| OLT-15 | 54kw | 28tons | 300-600kg/h | 11.25*2.8*4m | PLC(manual+automatic) | 5-8years |

| OLT-18 | 59kw | 40tons | 600-900kg/h | 12.5*3*4.5m | PLC(manual+automatic) | 5-8years |

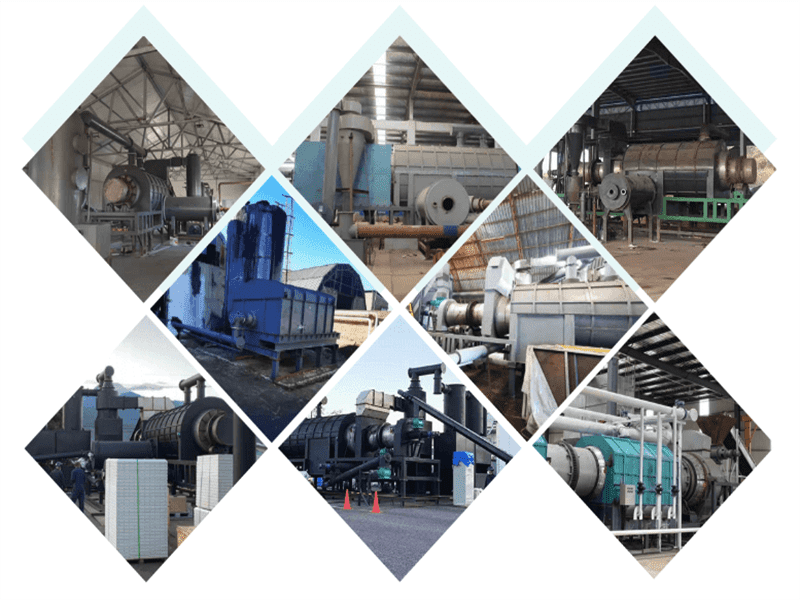

Continuous carbonization machine customer case

Want to know more about the process of Continuous Biomass Pyrolysis Machine , contact us.