The time of material carbonization is mainly distributed in the dehumidification stage, thermal decomposition stage, carbonization stage, and cooling stage. Among them, the longest time is the dehumidification stage and the cooling stage.

BiIf the moisture is too large, the dehumidification time will be longer.

Biomass wood charcoal briquette making machine uses heating ring adopts ceramic heating ring, which has high thermal efficiency, stability and safety.After the carbonization is completed, the temperature is higher, and the carbon must be cooled before taking the carbon, otherwise it will burn when exposed to air, causing unnecessary safety accidents.

In addition, longer cooling time will help the carbon shrink and the quality of the carbon will be better. Under normal circumstances, the cooling time is required to be more than 10 hours. If you need to speed it up, you can perform water cooling when the material temperature drops to about 100°C.

Therefore, the time period of carbonization mainly depends on the type of material and moisture.

For example:

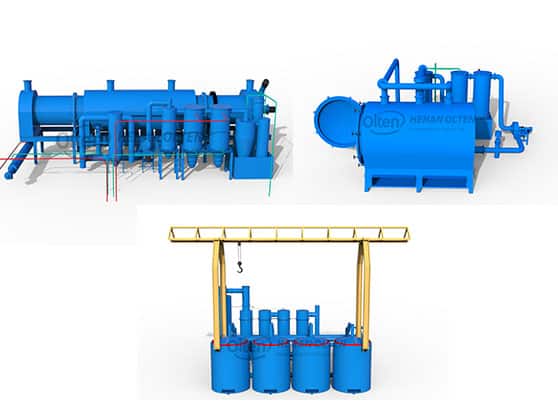

Hoisting carbonization furnace:

Taking logs with a diameter of less than 10cm and a moisture content of less than 15% as an example, the carbonization time is more than 10h, and the cooling time is more than 10h.

Horizontal carbonization furnace:

Taking logs with a diameter of less than 10cm and a moisture content of less than 15% as an example, the charring time of the log is 8-10h, and the cooling time is more than 10h.

Continuous carbonization furnace:

Take the sawdust material with a thickness of less than 30mm and a moisture content of less than 15% as an example. The temperature in the furnace is 300°C and the furnace body temperature rises to 600°C. It takes about 45 minutes from blanking to discharging.